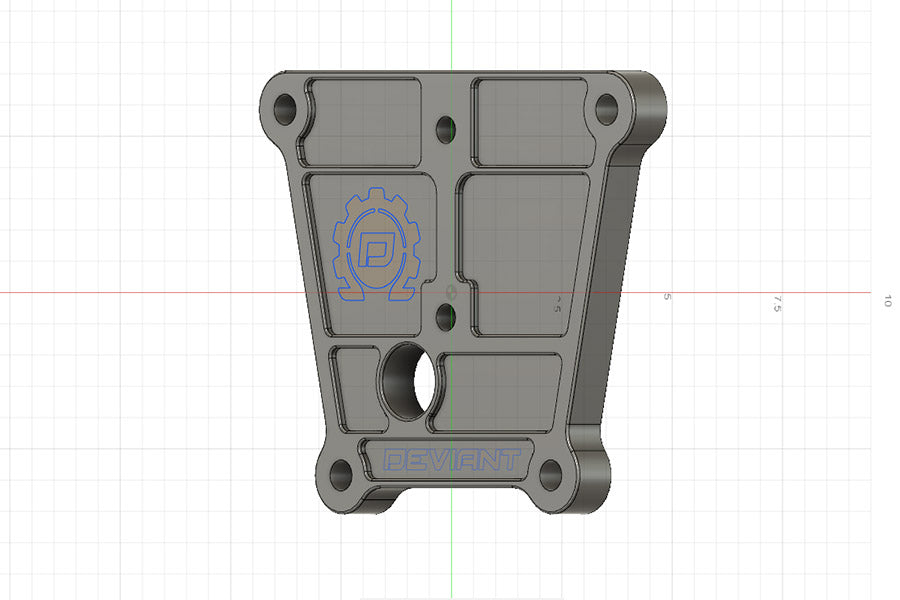

RZR Rear Radius Arm Plate R&D - Part 2 : Final Design

After some design updates and strength pull tests, (as talked about and show in “Strength Tested - RZR Radius Arm Plate R&D Part 1: Material & Design Tests”) we are down to finalizing the appearance. The actual structure and machining depths had already been finalized before we did our strength tests and we did not want to vary much off of that due to the fact it was a tested and proven design.

We did minor adjustments to the CNC program to make the tooling give the product a unique machined look. This is a top of the line quality machined product and we did not want to run it through a tumbler which would take away some characteristics and dull the finish.

When an aluminum surface is anodized it does not coat or change the sheen of the metal, it compliments it. If the aluminum plate is tumbled to a matte finish the anodizing will have a flat finish, if the aluminum is polished then the anodized finish will have a much glossier look to it, and that’s what we want.

After the anodizing process, we finish off the look by milling our Deviant logos on the plates which contrast the black perfectly.

Next Test… Real-world…