RZR Rear Radius Arm Plate R&D - Part 1 : Strength Tested

It’s no question that an aftermarket radius arm plate will add rigidity to the rear end and if you ride aggressive than an upgrade is a recommended addition. We researched the aftermarket radius arm plate world learning that there are many variants out there ranging from different materials, sizes, thicknesses, with and without D-rings and so on. There are some very reputable manufacturers and designs out there and there are some questionable cheap versions out there, but what we could not find was testing data.

Where are the weak spots? What material works best? What is the breaking point of these pull plates? The last thing I would want is to be in a situation where I am trying to pull a buddy out of a mud hole, thinking I have the proper equipment to do so, only to rip off the D-ring or the whole rear radius arm plate for that matter!

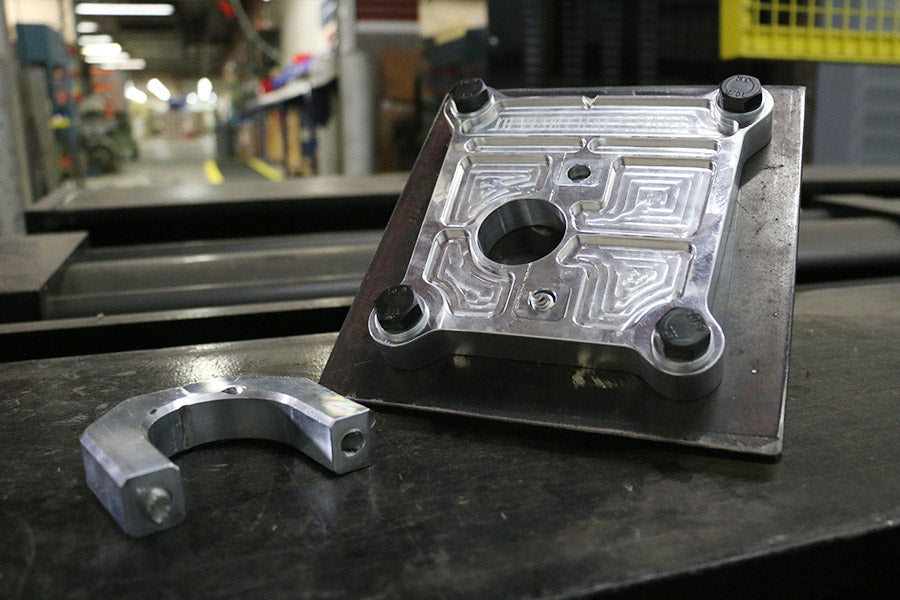

After we felt we learned enough from what the aftermarket world could show us, it was time to build our own designs. Testing variants in thickness, steel vs. aluminum construction, and doing our best to cover what we thought were the weak points. On top of designing plates that could withhold the abuse, we added in our own style and flair while adding extra functionality by including a rear differential oil port so that the rear plate would not need to be removed to do general maintenance.

Prototypes Done. Time to Test.

From our results, we found that the fabricated steel hook plate held the least amount at its breaking point of 9,451lbs. Which thinking about it 10k is still a respectable number. It basically has the strength to hold a 1-ton pickup upside down with minimal deflection.

We tested the ½” billet aluminum pull plate in multiple pound increments (5k, 10k, 15, and breaking point). By the 3rd pull at 15,000 pounds, we saw about a 1/16” deflection in the middle of the plate but it was still holding strong. Once we crested that 20,000-pound mark the center of the plate had about 1/2” deflection in the center. Then at 21,427lbs both the grade 8 bolts holding the D-ring on popped.

The ½” pull results for both the RZR 1000/XP Turbo and the Turbo S plate were identical. Breaking just beyond 21,000lbs and deflecting the plate about a ½”.

Though we knew that 21,000+lb holding weight was an extremely satisfying number and we knew the breaking point was the grade 8 bolts holding the D-ring on we wanted to strengthen the product even more. The only way to get around those grade 8 bolts sheering off would be to increase the bolt size which would lead to increasing the D-ring material around it. We didn’t really want to that as we feel that 21,000+lbs is plenty for these 1,600lb machines. What we did want to prevent was the deflection in the plate itself, I mean worst-case scenario, you somehow break the D-ring off, and then you just replace the D-ring and bolts, not the whole unit.

So we increased the plate thickness to 3/4” and the breaking point results were the same except there was absolutely no deflection in the plate itself. To put this in perspective, this ¾” billet aluminum pull plate is strong enough to lift a semi-truck (without trailer) off the ground and let it hang upside down without any deflection or breakage!!